3D Printer Plans News Round Up For 14/04/2014

Students Use 3D Printing To Build Eco-Car Of The Future

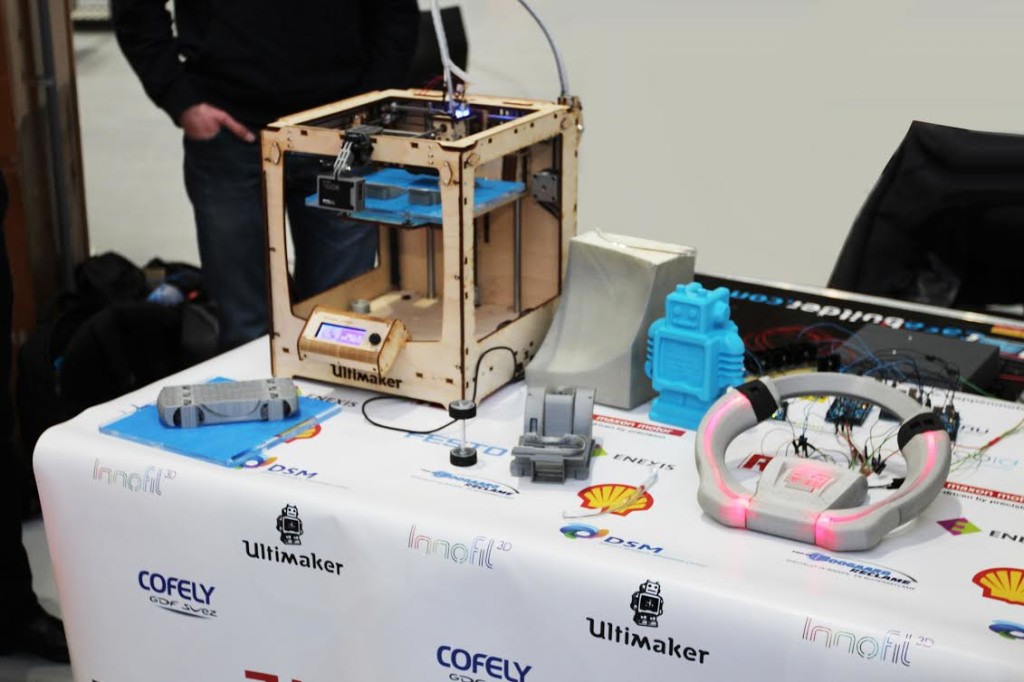

Students at Zuyd University of Applied Sciences are participating in the 2014 Shell Eco-marathon with a car that utilizes 3D printing to save weight and ultimately fuel. This is the fifth time the University has participated in the Shell competition, but they’ve partnered with Ultimaker this year to bring 3D printing to the table.

The ten desktop 3D printers supplied by Ultimaker have printed car parts like the dashboard, steering wheel, mirrors and handles. On top of that, 220 molds have been printed to make the carbon fibre parts for the body of the vehicle.

Professor Rob van Loevezijn of Zuyd University’s Faculty of Beta Sciences and Technology stated: “The main goal is to make a car that is as sustainable as possible, and the energy consumption must be as low as possible. 3D printing has been chosen because this technology is budget and environmentally friendly. The PLA plastics used in the 3D printer are environmentally friendly and biodegradable. Making the moulds with a 3D printer is also a lot faster than making the traditional wooden moulds.”

Amaker 3D Printer Heading To Kickstarter

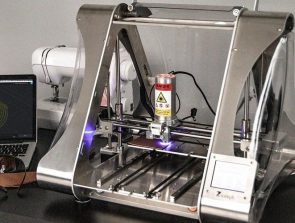

Singaporean company, Amaker3D will be launching a Kickstater campaign for their Amaker 3D printer. The Amaker has been equipped with next-gen control boards, dual ARM 32 bit processors, a rigid aluminium frame and threaded lead screw stepper motors for incredibly smooth action.

Shufen Yeo, Amaker3D’s co-founder said “Designed with users’ experience in mind, we’ve added a full color touch screen LCD to allow easy control of the entire printer. Various printer actions have been coded into selectable utilities for easy activation via LCD. Amaker 3D printer empowers users to print in multi colors. Users can easily switch colors anytime during the printing process.”

The Amaker features a 230 x 140 x 175mm build volume, a heated print platform with assisted bed leveling and an impressive 20 micron layer resolution. It can take both PLA and ABS filament with a diameter of 1.75mm.

“To ensure good 3D printer performance, our beta printer prototype has been subjected to three months of vigorous stress testing. Hot end has been tested to function at a high temperature up to 315°C. These testing results showed that we have a robust 3D printing solution.” says Siew Hong Goh, Amaker3D’s co-founder.

Amaker3D will launch the campaign on April 19. Stay tuned for further information.

3D Printing Chocolate Bunny Molds

3D printing has the potential to completely revolutionize medical and industrial industries, but some of us just want to use it for a bit of fun. CAPINC has uploaded a video showing off 3D printed chocolate bunnies that their staff have created for Easter. The company says 3D printing can be a great alternative to injection and machined molds. “It not only cuts manufacturing time, but is a most cost effective alternative.” They used a Objet30 Pro to print the molds for the bunnies.